Working Principle Of Mini Gold Dredge

Trommels are installed on a small angle to the horizontal or use a series of internal baffles to transport material along with the cylinder.

When the feeding material enters the roller trommel, due to the tilt and rotation of the trommel, the material on the screen surface is turned and rolled, so that the qualified material (under-screen product) is discharged through the outlet at the bottom of the rear end of the roller, and the unqualified material (upper-screen product) is discharged through the discharge port at the rear of the trommel.

Advantages Of Mini Gold Dredge

- Portable, small in size: easy to operate, maintain, transport and assemble, it is most ideal equipment for personal gold mining in mini river channel.

- Hot sale all over the world: Had been exported to more than 15 countries, such as Ghana, Philippines, Vienam, Russia, North Korea, Indonesia, Gabon, America and so on.

- High efficiency: It is equipped with a gold chute with gold carpet for high recovery rate.

- Quick return, high profits: It is highly efficient with low cost, a good gold mining machine.

- Standard quality: Diesel engine power system, float framework is made up of stainless steel structure, the floating body is made of high strength and light weight plastic, which means the main body of the machine is stong, durable and low failure rate.

- Customization design: According to the different geological condition, capacity requirement planning and the customers budget, provid the most ideal product for investor.

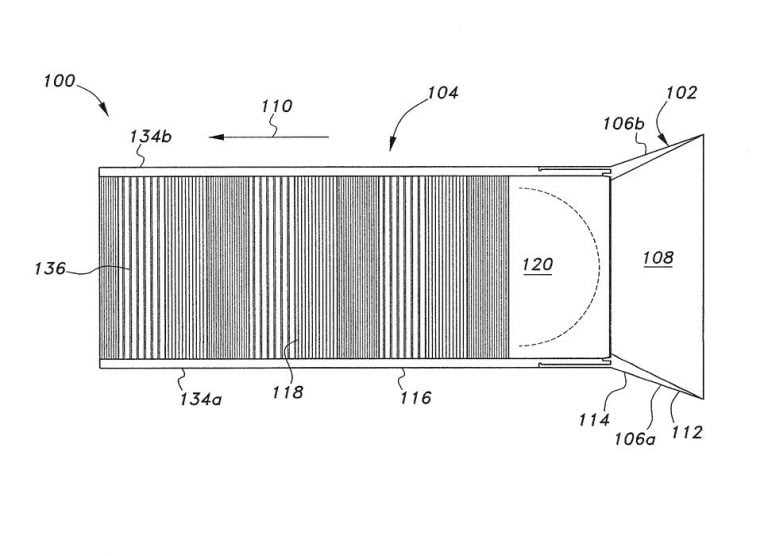

Structure

The Mini Gold Dredge is a small piece of equipment designed to excavate, screen and recover gold particles in water. It usually consists of an excavation bucket, engine, float and sifter, and the overall structure is compact, suitable for small-scale gold mining and exploration work.

Specification

After-sales service

Equipment installation and commissioning: professional technical team to guide the installation and commissioning, to ensure that the equipment is put into operation smoothly.

Technical training: provide comprehensive technical training and operational guidance to ensure that you master the equipment operating skills.

Warranty service: the main parts of the equipment enjoy warranty service, so that you can buy worry-free.

Maintenance support: provide fast response maintenance support services to ensure that equipment failures are resolved in a timely manner.

Parts supply: provide original parts supply service to ensure the continuous and stable operation of the equipment.

Zoneding Mining Machine

Zoneding Mining Machine